MDM 3 Series & Winder | checks, selects & creates Patient Pouch-rolls

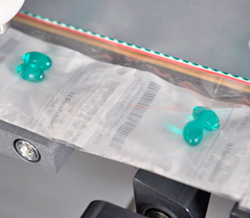

The MDM 3 series & Winder checks and automatically winds the pouches onto a roll, cutting and labelling as required.

The MDM 3 series automatically checks and re-checks the content of every unit- and multi-dose pouch and compares it with the expected content that is stored in its library. Data gathered by the MDM, including details of the pills, patient information, and a colour image of each pouch, are stored for security and accountability. The MDM Winder collects the pouches as they leave the detection machine in a single, smooth process that matches the speed of the MDM output.

Software intelligence

The MDM is connected via a computer network to the tablet packaging machine control software, so that the MDM knows the content(s) of each pouch it examines. Using a number of software algorithms, the MDM reads the pouch bar code and quickly and accurately checks the shape, colour and number of pills. The system includes a vibration table to ensure pills are not lying on top of one another and a colour image capture to store a photographic record of each pouch for security and accountability.

Double check

Any pouches with incorrect contents are marked by the system for re-view in the software program MDC. All data gathered by the MDM, including details of the pills, patient information, and the photographic record of the pouch, are then passed to the system library.

The MDM then feeds the pouches through to the units output, where they can be collected in a tidy roll created by using the specially designed MDM Winder. The winding process matches the speed of the MDM output. It is not required to stop the machine in order to begin winding a new roll or to remove a complete roll from the machine ñ the MDM Winder takes care of everything.

Useful library

When in programme mode, the MDM can gather details of all of the tablets it will need to recognize. The information of each tablet, including a colour image, is stored in its library. If this information requires updating while the MDM is in use, the Vision Station can be used to change these details or add new pills to the library.

Features

- Handling of different types of pouches

- Accurate checking of up to 75 pouches/minute

- Captures a colour image of each pouch for accountability

- Saves detailed information for process control and provides statistics for process overview in MDC and MDM-System Web

- Rolls with rejected pouches are separated, making them easy to collect.

- Continual process which matches the speed of the MDM output

Specifications

Technical specifications:

- Power: 220V~50Hz 6A or

- 110 V~60Hz 12A

- Air pressure: 6 Bar

- Includes UnWinder unit

Dimensions:

- Width: 740 mm

- Length: 1700 mm

- Height: 1870 mm

- Weight: 375 kg